Europe steps up commitment to decarbonization of steel production with renewable hydrogen

The European Union continues to pursue its goal of decarbonising its steel production through renewable energy sources such as green hydrogen. The latest beneficiary countries have been Germany and France, which will receive €2 billion and €850 million, respectively, for these decarbonisation processes.

As reported by the European Commission, in the case of Germany, Commission approved German €550 million direct grant and conditional payment mechanism of up to €1.45 billion to support ThyssenKrupp Steel Europe in decarbonising its steel production and accelerating renewable hydrogen uptake. The measures will contribute to the achievement of the EU Hydrogen Strategy, the European Green Deal and the Green Deal Industrial Plan, while helping to end dependence on Russian fossil fuels and fast forward the green transition, in line with the REPowerEU Plan.

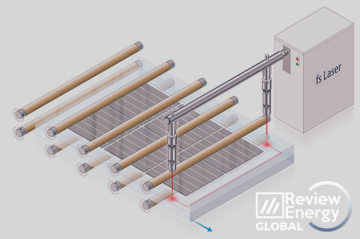

The direct grant will support the construction and installation of a direct reduction plant and two melting units in Duisburg, which will replace an existing blast furnace. Natural gas, initially used for the operation of the new direct reduction plant, will be gradually phased out and, as of 2037, the plant will be operated using only renewable hydrogen.

The conditional payment mechanism will cover, during the first ten years of operation of the new direct reduction plant, the additional costs of procuring and using renewable hydrogen instead of low-carbon hydrogen. The application of the conditional payment mechanism is subject to yearly verifications by an independent expert on the actual volumes and price paid for the renewable hydrogen consumed. tkSE will organise a competitive tendering process to select hydrogen suppliers, which the German authorities will monitor.

The new installations are envisioned to start operating in 2026 and are expected to produce 2.3 million tonnes of hot metal per year with reduced CO2 footprint, which will substitute an equal quantity of hot metal currently produced through the conventional blast furnace route. Once completed, the project is expected to avoid the release of over 58 million tonnes of carbon dioxide over the project lifetime. tkSE has committed to actively share the technical know-how gained through the project with industry and academia.

Germany selected tkSE's project in the context of an open call in 2021, to form part of an IPCEI on hydrogen technologies and systems. tkSE's project intends to reduce greenhouse gas emissions in the beneficiary's steelmaking processes. As aid for the reduction of greenhouse gas emissions, including through support of decarbonisation projects, is one of the main categories of aid allowed by the CEEAG, the measure was best suited for assessment under these guidelines.

The French measure

France notified to the Commission a €850 million measure to support ArcelorMittal's project aimed to partially decarbonise its steel production in Dunkirk, where it operates three blast furnaces producing liquid hot metal from a mixture of iron ore, pellets, coke, coal and preheated air. It also operates three basic oxygen furnaces which convert the liquid hot metal into liquid steel.

The aid will support the construction of a direct reduction plant (‘DRP') and two electric arc furnaces (‘EAF'). The combined DRP/EAF installation will substitute two of the three existing blast furnaces and two of the three basic oxygen furnaces. Natural gas, initially used in the DRP, will gradually be phased out of the steel production processes. Ultimately, the new installation will operate using exclusively renewable or low-carbon hydrogen, biogas and electricity as energy inputs.

Under the scheme, the aid will take the form of a direct grant paid out in four instalments during the construction period of the DRP/EAF installation planned between 2023 and 2026. The combined DRP/EAF installation is envisioned to start operating in 2026 and it is expected to produce 4 million tonnes of low-carbon liquid steel per year. Once completed, the project is expected to avoid the release of around 70 million tonnes of carbon dioxide over the 15-year lifetime of the project. ArcelorMittal has committed to actively share the experience and technical know-how gained through the project with industry and academia.

According to the Commission, France selected ArcelorMittal's project in the context of an open call in 2020 to form part of an IPCEI on hydrogen. ArcelorMittal's project intends to reduce greenhouse gas emissions in the energy-intensive steel sector. As aid for the reduction of greenhouse gas emissions, including through support of decarbonisation projects, is one of the main categories of aid allowed by the CEEAG, the measure was best suited for assessment under these guidelines.

.gif)

Comentarios

Sé el primero en comentar...